Our Services

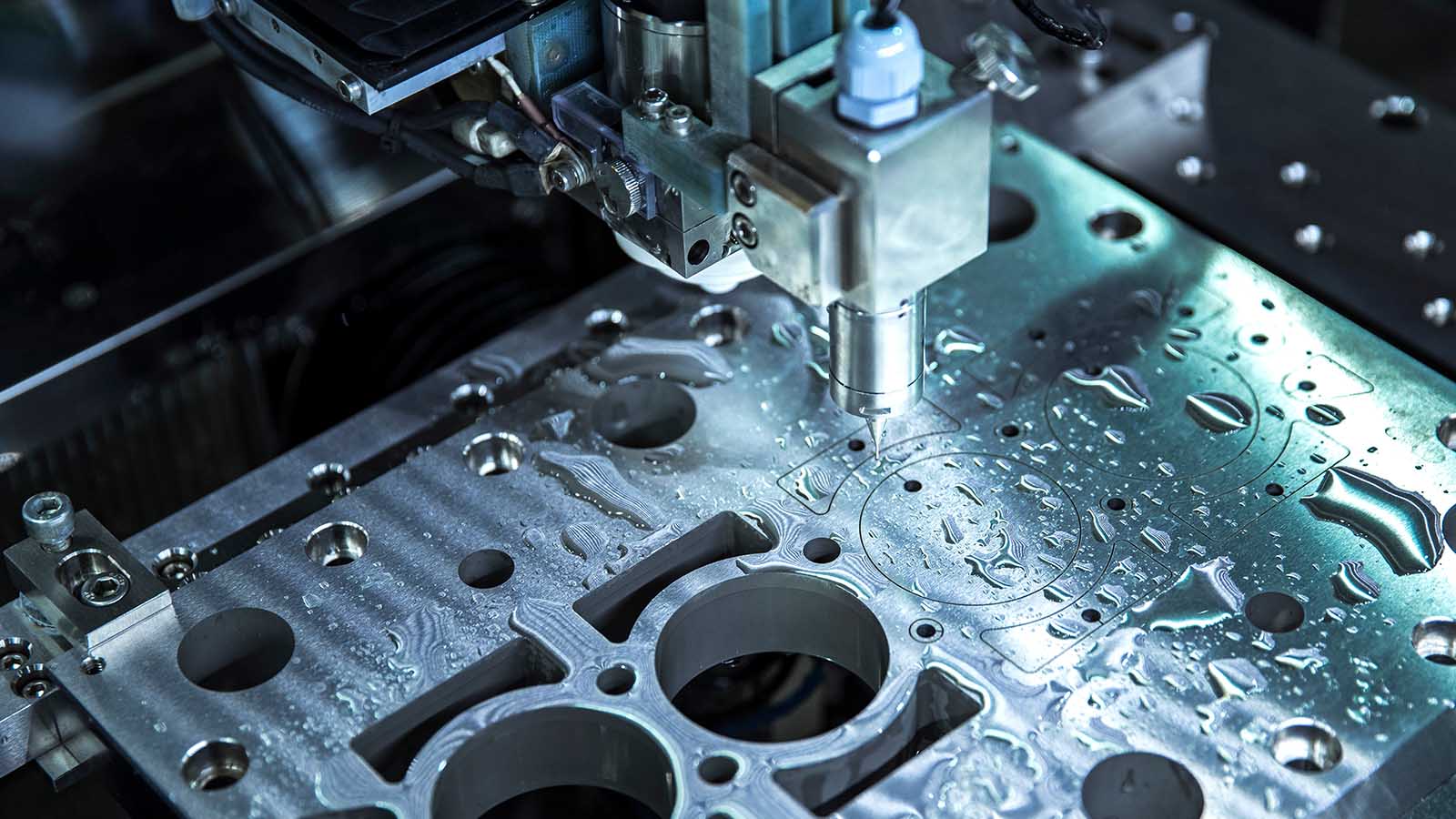

CNC Machining

CNC machining encompasses both CNC milling and CNC turning, serving as fundamental processes in precision manufacturing. This advanced technique operates at high speeds to meticulously sculpt parts by subtracting material from a solid block or billet.

Driven by coded instructions, CNC machining orchestrates machine movements, spindle speeds, and other parameters with remarkable precision. By relying on numerical control, it enables automated and reproducible operations, minimizing the need for manual intervention. Beginning with the translation of 2D or 3D CAD designs into machine-readable code, CNC machining undergoes rigorous testing to ensure accuracy. It stands as a cornerstone in the fabrication of metal and plastic components across diverse industrial sectors.

CNC machining presents numerous benefits for product developers, enhancing design flexibility and enabling a multitude of options:

- Parts retain full strength

- Ability to fabricate parts with intricate shapes and contours

- Achieve exceptional surface finishes

- Maintain tight tolerances and achieve high precision

- Ensure uniformity across products

- Facilitate high-volume production and scalability

- Easily customizable to suit specific requirements

- Applicable to a diverse array of substrates

- Compatibility with a wide range of materials, including metals, plastics, and composites.

High Pressure Die Casting (HPDC)

For over 20 years, We are leading provider of aluminum and zinc die castings, catering to the global market’s low-to-medium volume needs. Our steadfast commitment lies in maximizing the value of each part for clients spanning various industries.

Industries Served

- Architectural Hardware

- Medical

- Automotive

- Hand Tools

- Military & Ordnance

- Die casting offers the production of intricate shapes with tighter tolerances compared to numerous mass production techniques. It operates at high rates, often requiring minimal to no additional machining.

- Furthermore, die castings boast thinner walls compared to alternative casting methods, while still achieving greater strength, surpassing plastic injection moldings of equivalent dimensions.

- The resulting parts from die casting are characterized by their durability, dimensional stability, and premium look and feel, reflecting a commitment to quality craftsmanship.

- Die castings are monolithic structures, integrating multiple functions into a single, intricately shaped component. Unlike assemblies comprising separate parts joined by welding or fastening, die castings derive their strength solely from the material itself, rather than relying on the integrity of threads or welds. This inherent unity ensures robustness and structural integrity, enhancing the reliability and performance of the final product.

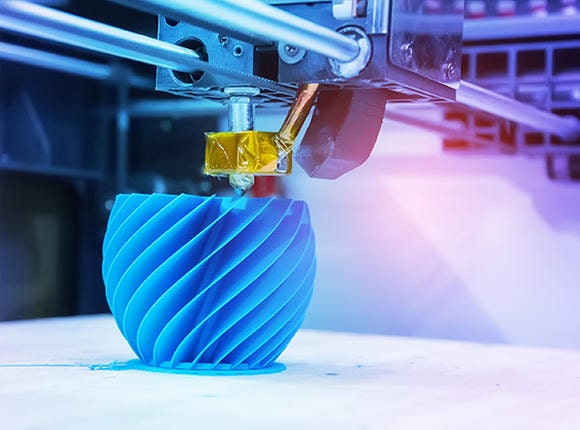

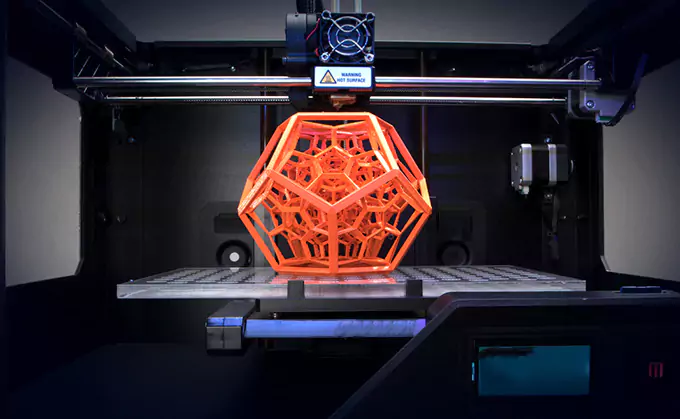

3D Printing Services

- STC stands as a premier provider of online 3D printing services, offering unparalleled convenience and speed. Whether you require prototypes or production-grade parts, we deliver on-demand solutions with rapid turnaround times, often as quick as a single day. As your comprehensive source for precise and customized 3D-printed components, we ensure affordability without compromising on quality.

- Simply upload your 3D CAD file to receive an instant online quote and lead time estimation within seconds. Our extensive capabilities encompass a vast selection of over 60 metals and plastics, enabling us to fulfill diverse requirements with accuracy and reliability.

- At STC, we leverage cutting-edge additive manufacturing technologies to produce functional parts at competitive prices. With access to eight top-tier 3D printing processes, including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, PolyJet, Carbon DLS, Nexa3D LSPc, binder jet metal, and HP Multi Jet Fusion, we ensure exceptional results tailored to your specific needs.